Shipping packaging: how to protect your products during delivery

As shipping packaging is a booming business in its own right, with logistics experts around the world eagerly awaiting the development of new materials and more sustainable options.

When it comes to choosing the ideal package, protection capacity is the most important factor to consider. After all, damaged or broken shipments mean losses for your business.

How to choose shipping packaging for your products

Choosing the perfect packaging to ensure your products survive the shipping process It’s essential to keeping your customers happy.

Filling packages with appropriate materials helps stabilize items as they travel to their intended destinations. However, you need to know exactly what to use.

Finding shipping packaging that works well for the types of products you sell is part of the core of your business, and it certainly impacts your growth.

Let’s take a look at some popular options on the market and what their pros and cons are.

Air cushions

The air cushion is a relatively new solution in the world of shipping packaging, but it has already earned its place in many companies.

Pros

- They are non-abrasive, making them a great match for smooth items that are easily scratched.

- They are great for filling large voids in your packaging, without the cost associated with denser fill options.

- They are normally inflated as needed with a special machine. This makes them much more easy to transport and store than common alternatives.

Cons

- May not be suitable for items with a high risk of breakage.

- They don’t work well for particularly heavy products or items with scalloped edges.

Air cushions are commonly used when shipping the following product categories: electronics, sporting goods, and home decor.

Kraft Paper

Kraft paper is a simple shipping solution which avoids problems with scratches and damage during transportation. It can also be used to improve presentation and customer post-purchase experience.

Pros

- Can be used creatively to provide an unpacking experience more pleasant for your customers.

- It is versatile and can be rolled or stacked as a void filler in any size box.

- AND recyclable by e-commerce retailers and consumers.

Cons

- Shaping the kraft paper to fill empty spaces can take time.

- This option may also weigh more than other alternatives, increasing your delivery costs.

Kraft paper is commonly used when shipping the following product categories: books and heavy goods.

Bubble Wrap

The once-ubiquitous bubble wrap has seen its popularity decline with the sudden adoption of air cushions, but this iconic filling for shipping packaging still meets safety needs and remains in use.

Pros

- It offers quite exceptional protection for even the most fragile items when used correctly.

- Helps reduce the amount of packaging space your shipments require, eliminating unnecessary expenses in the process.

Cons

- This material is not environmentally friendly.

- Bubble wrap is also a little difficult to store. Because it takes up a lot of space when not in use, it is less efficient than other alternatives.

Bubble wrap is commonly used when shipping the following categories of products: small and fragile items, large and heavy items (even furniture).

Shredded Cardboard

Cardboard is one of the main components of shipping processes, but this material can also be used to add padding to shipping packaging.

Pros

- Could it be produced from recycled materials, which makes it a more environmentally friendly solution.

- Armed with an industrial paper shredder, companies can create their own shredded cardboard to fill shipping boxes.

Cons

- It’s not necessarily very soft, so it can cause scratches on fragile items.

Shredded cardboard is commonly used when shipping the following categories of products: small, heavy items (especially those made of glass), items with irregular shapes, and items with rough surfaces.

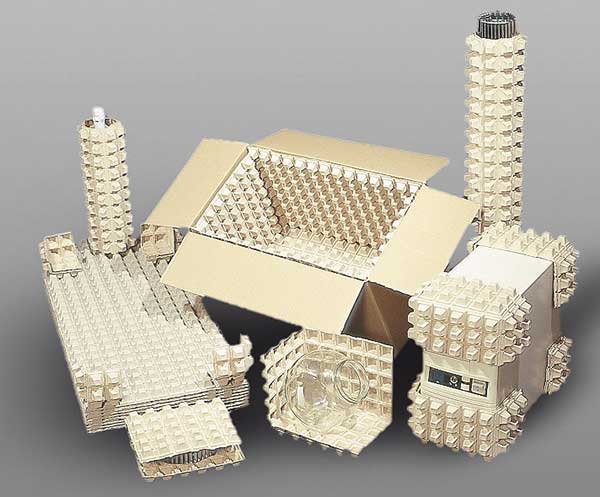

Molded Fill

Molded infills offer a degree of customization to delivery packaging that other options simply cannot.

Made from cardboard or Styrofoam, these fill materials can be shaped to match the contours of the box and the item itself. However, they are not a perfect solution for all cases.

Pros

- Highly customizable styrofoam molds and cardboard cutouts can secure almost any type of item.

- By adapting to the shape of the box, this form of filling helps to preserve the appearance of the outer packaging during transport.

- Options like molded pulp produce lightweight results that reduce shipping costs.

Cons

- They can be bulky to store before use.

- Molded padding made from Styrofoam is not particularly environmentally friendly.

They are commonly used when shipping the following product categories: high-value items, machines, and large electronic devices.

What types of shipping packaging should I choose for my e-commerce?

All shipping packaging options listed make it possible to protect products when delivering them – no matter how far they are traveling.

Ultimately, selecting the right option comes down to balancing effectiveness, ease of use, and estimated expense.

Your best bet will be the solution that fits your budget – without forcing an inconvenient unboxing experience on your customers or failing on product safety.

Now that you know how to package your products for shipping, all you need to do is find the right partner to make the delivery.

Specialized in e-commerce, the Delivery365 app enables the creation of your own e-commerce, also offering tracking technology, online shipping calculation, ways to receive payment online and direct connection with a base of hundreds of delivery people.

To learn more, visit our website, learn about our services and guarantee the best transportation of goods for your client.